Professuren am Institut

| Fachgebiet | Leitung |

|---|---|

| Werkzeugmaschinen und Fertigungstechnik | Prof. Dr. h. c. Dr.-Ing. Eckart Uhlmann |

| Handhabungs- und Montagetechnik | Prof. Dr.-Ing. Franz Dietrich |

| Qualitätswissenschaft | Prof. Dr.-Ing. Roland Jochem |

| Industrielle Automatisierungstechnik | Prof. Dr.-Ing. Jörg Krüger |

| Industrielle Informationstechnik | Prof. Dr.-Ing. Rainer Stark |

| Beschichtungstechnik | Prof. Dr.-Ing. habil. Christian Rupprecht |

| Mikro- und Feingeräte | Prof. Dr.-Ing. Dirk Oberschmidt |

| Fügetechnik | Prof. Dr.-Ing. Michael Rethmeier |

| Nachhaltige Unternehmensentwicklung | Prof. Dr.-Ing. Holger Kohl |

| Tribologie | Prof. Dr. Heinz Sturm |

| Digitales Engineering 4.0 | Prof. Dr.-Ing. Lydia Kaiser |

| Wissensdynamik und Nachhaltigkeit in den Technikwissenschaften | Prof. Dr. phil. habil. Dipl.-Ing. Sabine Ammon |

| Maschinen und Technologien für die Additive Präzisionsfertigung metallischer Bauteile | Prof. Dr.-Ing. Julian Polte |

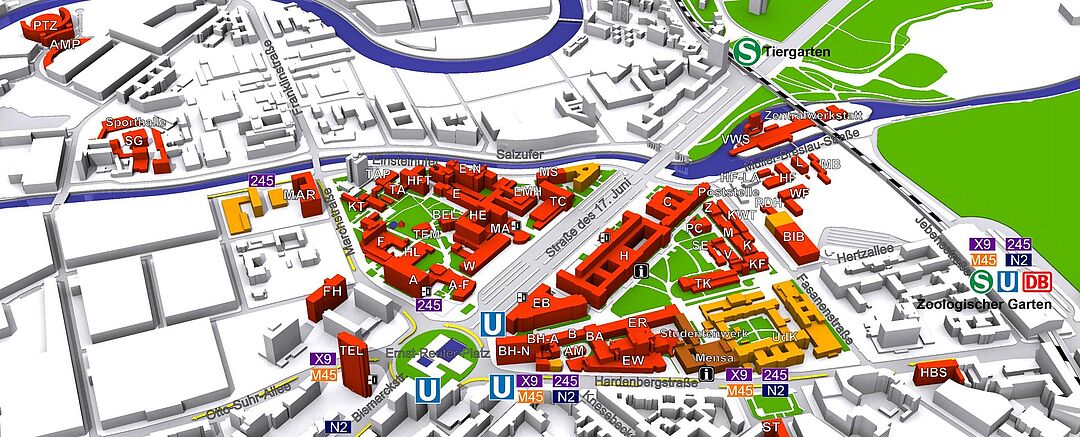

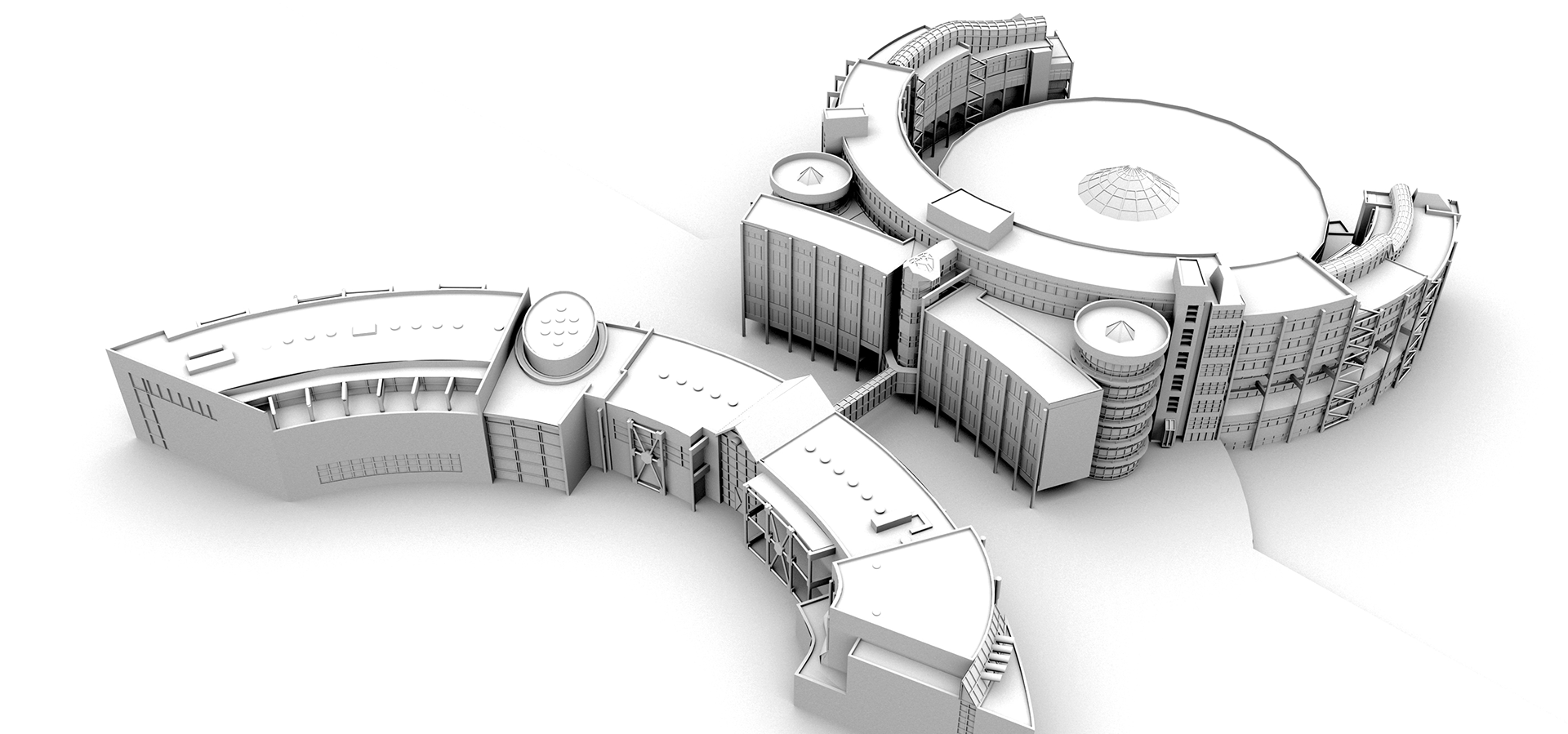

Unser Institut befindet sich gemeinsam mit dem Fraunhofer-Institut für Produktionsanlagen und Konstruktionstechnik im Produktionstechnischen Zentrum Berlin.

Standort des Instituts

Produktionstechnisches Zentrum (PTZ)

Anschrift

Institut für Werkzeugmaschinen und Fabrikbetrieb

Technische Universität Berlin

Geschäftsführende/r Direktor/in

c/o Dr.-Ing. Jörg Bold

Produktionstechnisches Zentrum

Sekretariat PTZ 1

Pascalstraße 8 - 9

D-10587 Berlin

Anreise

Bitte beachten Sie bei Anreise mit dem Auto die seit 1/2008 geltenden Regeln in der Umweltzone. Die Umweltzone ist das Gebiet innerhalb des S-Bahnringes, in dem nur Fahrzeuge fahren dürfen, die bestimmte Abgasstandards einhalten. Fahrzeuge mit besonders hohen Emissionen müssen draußen bleiben.

Bahn

Ab Berlin Hauptbahnhof »Lehrter Bahnhof«:

– mit dem Taxi (ca. 10 Min.)

– mit dem Bus 245 von der Haltestelle »Lehrter Straße/Invalidenstraße« in Richtung S+U Zoologischer Garten bis zur Haltestelle »Franklinstraße«; Fahrzeit etwa 20 Minuten. Zu Fuß in Fahrtrichtung etwa 200 m und dann rechts in die Pascalstraße einbiegen (ca. 5 Min.).

Auto

Aus Richtung Hannover, Leipzig, Nürnberg:

– A 115 nach Charlottenburg (A 100); A 100 bis Ausfahrt Kaiserdamm, dann B2 Richtung Tiergarten (Kaiserdamm, dann Bismarckstr.) bis zur Leibnitzstraße. Links abbiegen in die Leibnitzstraße, die im weiteren Verlauf zur Cauerstraße wird. Weiter über Helmholtzstraße, die wiederum die Fortsetzung der Cauerstraße bildet, bis zur Pascalstraße: links einbiegen.

Aus Richtung Hamburg, Rostock:

– A 111 nach Charlottenburg (A 100); A 100 bis Ausfahrt Kaiserdamm, dann B2 Richtung Tiergarten (Kaiserdamm, dann Bismarckstr.) bis zur Leibnitzstraße. Links abbiegen in die Leibnitzstraße, die im weiteren Verlauf zur Cauerstraße wird. Weiter über Helmholtzstraße, die wiederum die Fortsetzung der Cauerstraße bildet, bis zur Pascalstraße: links einbiegen.

Flugzeug

(an Berlin Tegel)

Mit dem Bus x9 Richtung S+U Zoologischer Garten bis U Ernst-Reuter-Platz. Dort in den Bus 245 Richtung Nordbahnhof umsteigen bis Ausstieg »Helmholtzstraße«. Der Straße in Fahrtrichtung 200m folgen und links in die Pascalstraße einbiegen (ca. 5 Min.).

(an Berlin Schönefeld)

– mit dem Taxi (40 Min.)

– S9 bis Hauptbahnhof »Lehrter Bahnhof«, mit dem Bus 245 von der Haltestelle »Lehrter Straße/Invalidenstraße« in Richtung S+U Zoologischer Garten bis zur Haltestelle »Franklinstraße«; Fahrzeit etwa 20 Minuten. Zu Fuß in Fahrtrichtung etwa 200m und dann rechts in die Pascalstraße einbiegen (ca. 5 Min.).

Lageplan

© Fraunhofer IPK

© Fraunhofer IPK